Electric Track Vehicles

Electric Track Vehicles (ETV) are autonomous trolleys or cars running on a monorail network.

Electric Track Vehicles provide an intralogistics solution that sits between between Pneumatic Tube Systems designed for small packages, and Automated Mobile Robots which provide solutions for heavier payloads.

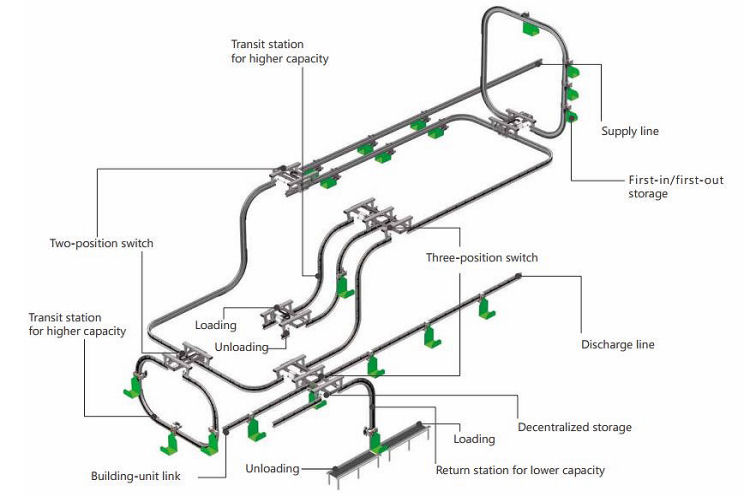

An Electric Track Vehicle installation comprises of a set of standard components (straight profile rails, bends and curve elements, various types of points, station terminals and much more), which are planned and designed to create a distributed network that can meet the logistical needs of the customer. Depending on load capacity and transport speed, the self-driving conveying trolleys (vehicles) comprise of several possible standard chassis types, and depending on load capacity and usage environment, numerous different designs of load handling devices which are attached to the base chassis. A decentralised, PLC-based TeleControl control system controls the transport jobs, as well as taking care of system monitoring and visualisation. The control systems communicate via a TCP/IP network, with communication to the trolleys themselves through a special CAN bus communicated through the track rails.

ETV systems deliver several benefits when compared to alternative intra-logistic conveyor solutions. These include:-

- The ability to operate both horizontally and vertically. When travelling vertically the vehicles engage with a rack and pinion system.

- Because each vehicle is operated and controlled independently from other vehicles within a network conveyor environment, the transport service can be one-to-many, many-to-one, or indeed several-to-several. What this means is that each transport journey within the network can be directed to complete the exact task required.

- Running on a monorail system that can accommodate both vertical and horizontal movement allows vehicles to present at low level for loading/unloading and then transfer to high level for inter-station travel. This keeps operational areas clear of logistics processes.

- Operating as an “on demand” conveyor system within a network environment ensures that each transport is carried out as efficiently as possible.

- Job allocation can be initiated either through HMI (Human Machine Interfaces) or via data from external controllers.

Electric Track Vehicle systems are available in two sizes. Unicar is the monorail conveyor system used for applications with lighter weight payloads up to around 15kg. Multicar is a larger system capable of transporting payloads up to 40kg. Both systems can be configured with various load handling devices, including conveyor platforms for transporting e.g. tote boxes.

Unicar

Unicar is the Electric Track Vehicle system for payloads up to 15kg. The principal applications for Unicar are within Healthcare and Libraries

Multicar

Multicar is the Electric Track Vehicle system for payloads up to 40kg. The principle applications for Multicar are found within industrial manufacturing and processing.

Contact us today to find out how our solutions can help you.