MINERALS CLEAN UP

For a minerals processing company, Quirepace BVC has delivered a central vacuum cleaning/bulk removal system that will serve many floors and remove calcium carbonate grains and powders (up to 40mm in size).

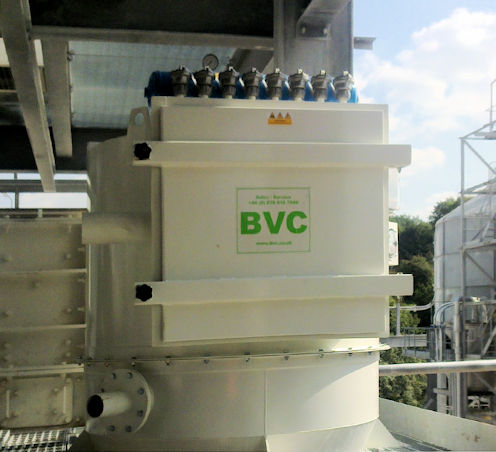

To maintain and manage a clean environment where conventional vacuum cleaners were not an answer, the solution – installation of a pipe work system interconnecting strategically positioned hose connection points, these are connected to a vacuum plant comprising filter separator and exhauster package.

Materials are entrained into the airstream and conveyed to the filter separator, where the heavier solids are disengaged, dropping down into the hopper section with lighter materials and conveying air rising towards the filtration media which is cleaned by reverse jet. Products are dispensed by a double dump valve into a screw conveyor returning the collected materials back into the process.

The motive air is generated by an exhauster unit powered by an 18.5 kW motor. The unit is located on an automatic self- tensioning drive system, within a force draft ventilated acoustic enclosure with discharge silencer ensuring low noise levels. BVC also supplied the control panel housing, the exhauster, ventilation fan, motor starters and contacts with all instrumentation and with provision of contacts so that the system is connected to the clients Building Management System.