TWO FOR ONE

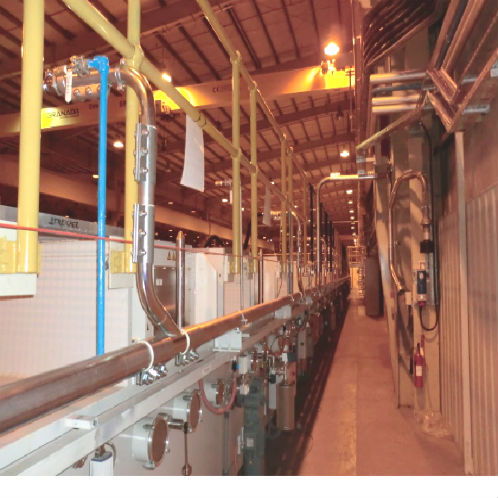

In order to finish a project for a manufacturer of float glass, Quirepace BVC supplied and installed two pipe work systems that were each separately connected to one of the business’s industrial vacuum cleaning machines.

This system serves the Glass Coater Line and has been designed for 3 people using 38 mm hoses and tools (hose lengths of up to 15 metres). Pipe work has been installed along the whole line length, 132 metres, interconnecting 20 hose connection points which are joined back to a BVC static industrial vacuum cleaning machine.

The system is designed for personnel to carry out superior vacuum cleaning duties from specific pieces of production equipment and surrounding area.

The BVC Centurion model Ti80 industrial vacuum cleaning machine is powered by a 15.0 kW motor, with the machine being protected by a vacuum relief valve which opens when no hoses are attached to the pipe system.

Displaced air is filtered within the BVC ‘clear flow’ filtration system and particles are collected within a removable bin at the base of the unit. This is equipped with a bin balance arrangement for use with plastic liners. The bin is provided with a ‘lift and tip’ forklift attachment to ease the transportation of the full bin and discharging the sealed bag for onward disposal.